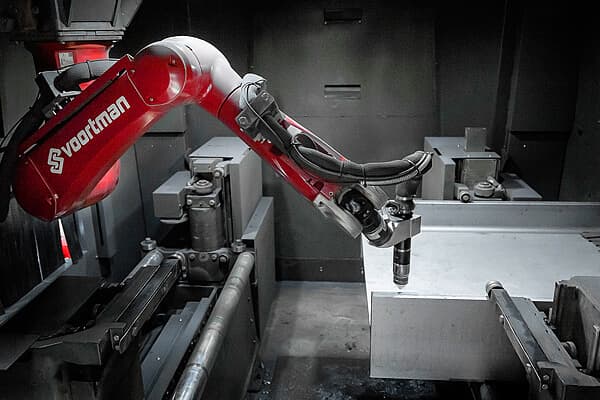

Robotic Coping Machines Pay The Best

We offer service for all types of structural steel fabrication machinery, such as beam coping and other machines. Get in touch with us to arrange a service time.

Our robotic coping machine is capable of cutting seismic structural connections (like "dog bone" and slotted web cuts), copes at product's beginning or end, holes of all sizes and shapes, block-outs and weld preparations as well as markings on all four sides.